In Hong Kong’s fast-paced industrial and commercial sectors, durability is important. This is especially true for rubber mats used in heavy-duty settings. Rubber mat suppliers play a crucial role in providing products that can withstand tough conditions.

These mats are used in various places, from busy factory floors to crowded gym areas. But how do suppliers make sure their mats last long and perform well? Let’s explore the ways rubber mat suppliers ensure their products meet the demands of heavy-duty use.

Quality Materials: The Foundation of Durability

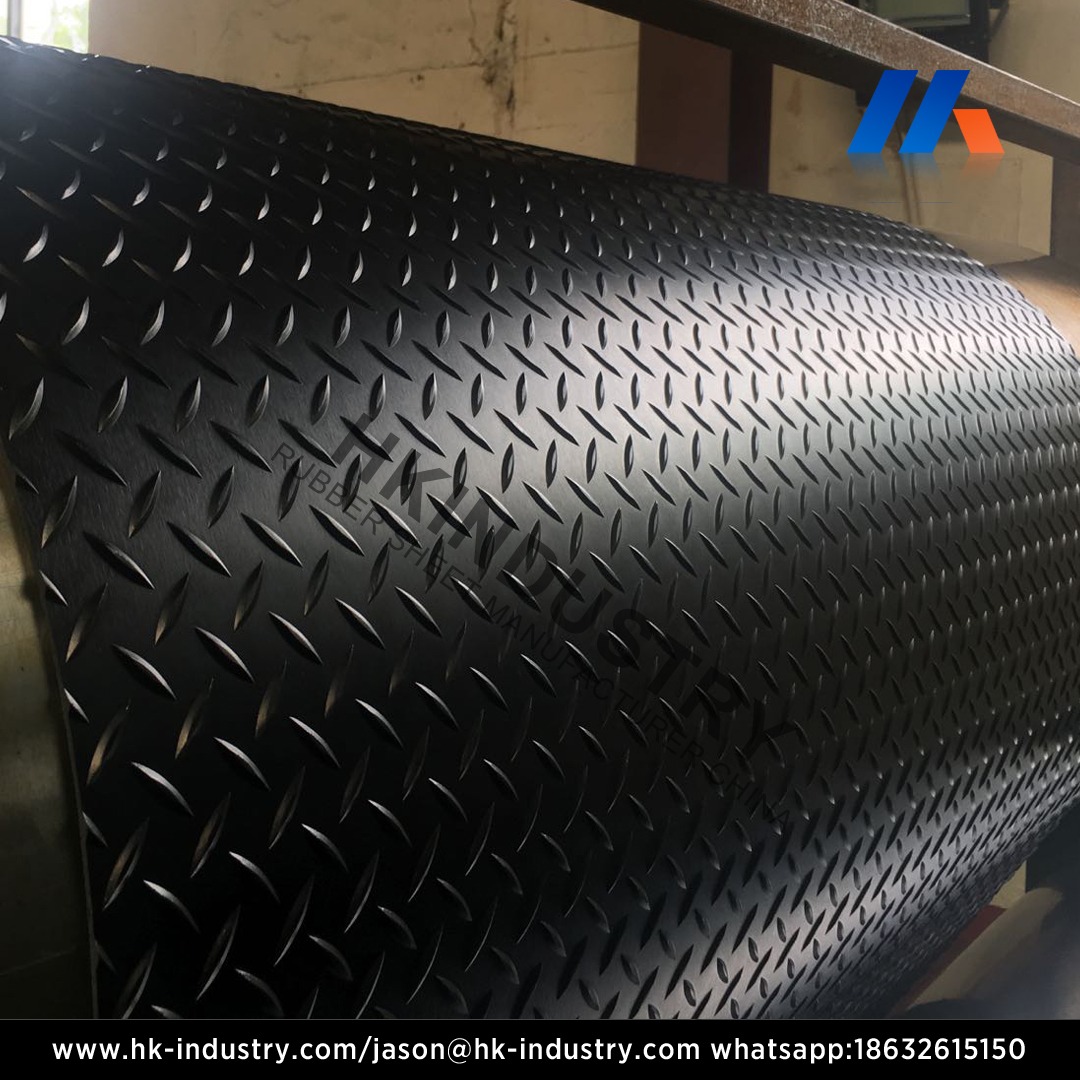

The journey to durable rubber mats starts with high-quality materials. Rubber mat suppliers in Hong Kong carefully select their raw materials. They often use a mix of natural and synthetic rubbers.

This blend gives the mats both strength and flexibility. Natural rubber provides elasticity and resilience. Synthetic rubbers add resistance to oils, chemicals, and extreme temperatures.

Some rubber mat suppliers also incorporate additives into their rubber compounds. These additives enhance specific properties of the mats. For example, they might add UV stabilizers to prevent sun damage. This is important for mats used in outdoor areas.

Advanced Manufacturing Processes

Having good materials is just the start, and how these materials are processed is equally important. Rubber mat suppliers use advanced manufacturing techniques to create durable mats.

One common method is vulcanization, and this process involves heating the rubber with sulfur. It creates strong bonds within the rubber, making it tougher and more elastic.

Many rubber mat suppliers use precision molding techniques, and these methods ensure that each mat has consistent thickness and density. This uniformity is crucial for even wear and long-lasting performance.

Rigorous Testing and Quality Control

Top rubber mat suppliers don’t just make mats and hope for the best. They put their products through rigorous testing. This testing simulates real-world conditions, often pushed to extremes.

For example, they might test how well a mat handles heavy foot traffic. They do this by subjecting it to thousands of simulated footsteps.

Customization for Specific Needs

Not all heavy-duty applications are the same, and a mat for a factory floor faces different challenges than one for a gym. Rubber mat suppliers in Hong Kong understand this. They offer customization options to meet specific needs.

Customization can involve changing the mat’s thickness, size, or shape. Suppliers might adjust the rubber compound to increase certain properties.

For instance, they could make a mat more oil-resistant for use in a mechanic’s shop, or they might add extra cushioning for mats used in standing workstations.

Ongoing Research and Development

The best rubber mat suppliers don’t rest on their laurels. They constantly work to improve their products, and this involves ongoing research and development efforts.

In addition to keeping up with the most recent demands and trends in the industry, suppliers make investments in new materials and technologies.

For example, some suppliers are exploring eco-friendly rubber alternatives; others are working on mats with enhanced antimicrobial properties.

Wrap-up

Rubber mat suppliers in Hong Kong go to great lengths to ensure their products are durable and long-lasting. Every stage is critical, from meticulous material selection to advanced manufacturing techniques.