Modern dairy farming requires careful attention to animal comfort and welfare, even in urban-adjacent agricultural operations across Hong Kong’s New Territories. Among the most impactful investments for cattle health and productivity, cow rubber mats rank near the top of the list. While they might seem like simple products, the quality and features of these mats directly influence animal well-being, milk production, and long-term operational costs.

Optimal Thickness and Cushioning Properties

The primary purpose of a cow rubber mat is to provide comfort for animals that spend significant time standing or lying on hard surfaces. Mat thickness directly correlates with cushioning performance and longevity. Professional dairy operations typically select mats between 18mm and 24mm thick, and finding this range offers the ideal balance between support and durability.

Beyond simple thickness measurements, assess how the cow rubber mat responds to pressure. Quality mats provide appropriate “give” under the cow’s weight without bottoming out completely. The cushioning effect should distribute weight evenly while still offering stability during movement. Many Hong Kong dairy farmers test mats by pressing firmly with their knees to simulate animal weight distribution before making purchase decisions.

Slip-Resistance for Safety

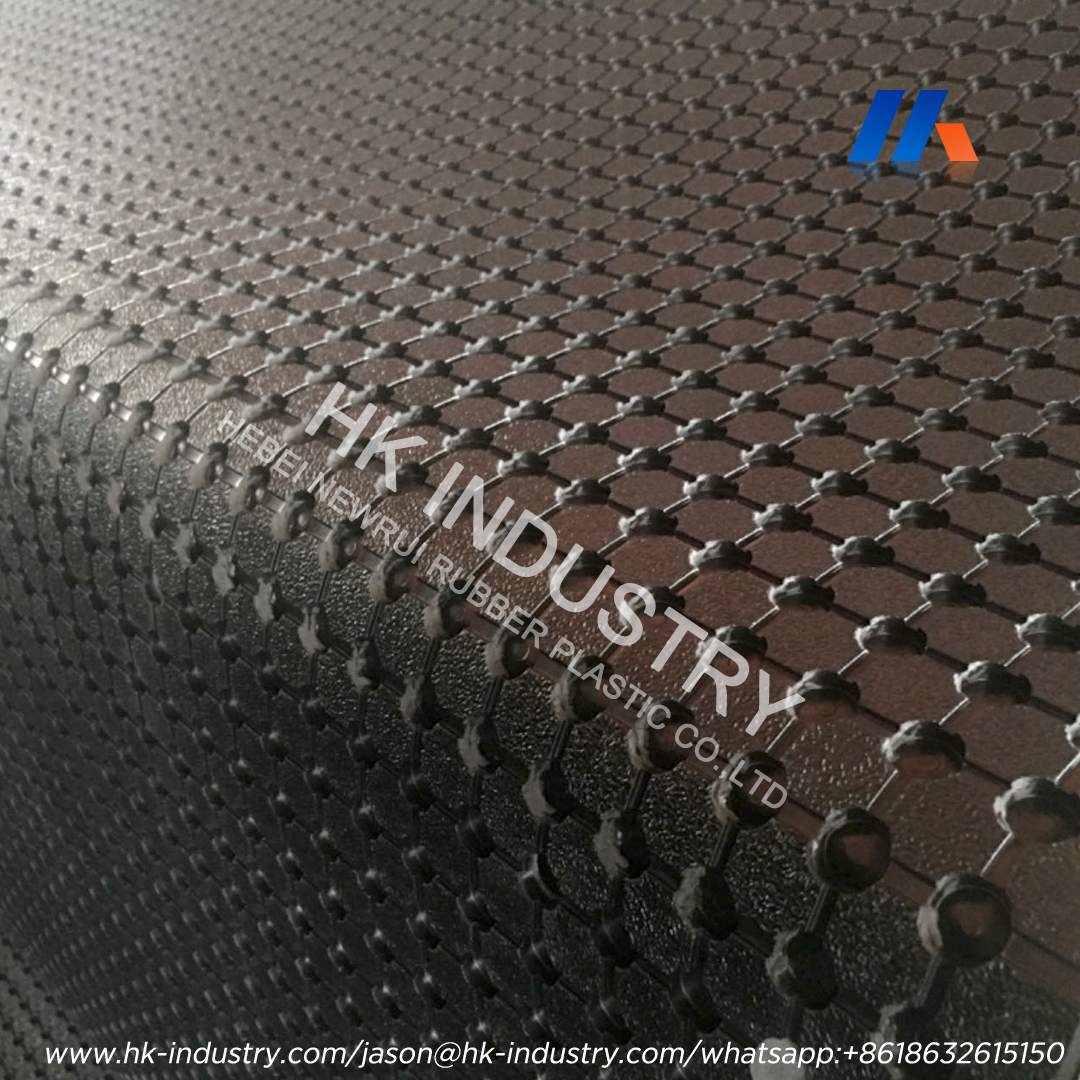

Preventing animal slips and falls remains crucial for both welfare and productivity. Quality cow rubber mats feature textured surfaces specifically designed to provide secure footing even when wet. The ideal texture provides traction without creating areas that trap moisture or harbor bacteria growth.

Hong Kong’s humidity presents particular challenges for flooring materials in agricultural settings. Superior cow rubber mats maintain their slip-resistant properties despite constant moisture exposure. Evaluating the surface pattern reveals much about mat performance, look for designs that incorporate shallow channels to divert liquid while maintaining sufficient contact area for stable footing.

Material Composition and Durability

The rubber compound used in manufacturing directly determines how long a cow rubber mat will maintain its beneficial properties. Premium mats utilize high-density virgin rubber formulations specifically engineered for agricultural applications. While recycled rubber options cost less initially, they typically degrade faster in demanding barn environments.

Quality manufacturers incorporate stabilizers and anti-degradation compounds into their cow rubber mat formulations to resist breakdown from ammonia exposure, cleaning chemicals, and UV radiation. Many Hong Kong farmers have found investing in higher-quality mats reduces replacement frequency, providing better value despite higher initial costs.

Installation System and Stability

The method by which cow rubber mats connect and remain in position significantly impacts their practical performance. Interlocking edge designs prevent mat separation and shifting that could create hazardous conditions. Puzzle-style connections generally outperform simple butt joints for maintaining alignment over time.

Drainage and Cleaning Efficiency

Maintaining proper hygiene directly influences animal health and production quality. Superior cow rubber mats incorporate design features that facilitate efficient cleaning and moisture management. Slightly sloped surfaces combined with strategic drainage channels help liquids flow toward collection systems rather than pooling on mat surfaces. The rubber composition should resist the absorption of liquids and odors while allowing thorough cleaning with standard barn equipment.